Tutorial Video

Work Instruction

Prerequisites: You must have items created before proceeding to this step, including both ingredients/components as well as the product that will be yielded.

A Packaging Recipe allows you to create a set of instructions on how to manufacture a product from its ingredients, usually a bulk item and packaging materials.

To create a Packaging Recipe, select the Packaging Recipe icon from the display menu or click Master Tables >> Recipe Manager >> Packaging Recipe.

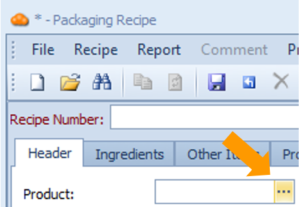

Select New:

Select the product that will be yielded:

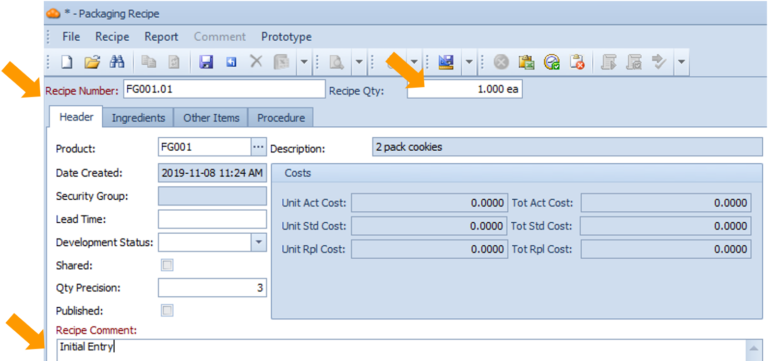

Enter a Recipe Number and a Recipe Comment on their respective fields. The form also assumes that the standard recipe yield would be 1 of the product’s unit; this may be changed at your discretion by entering the amount in the Recipe Qty field.

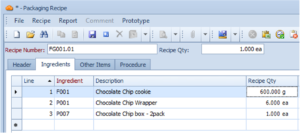

Packaging Recipe Ingredients

Select the Ingredients tab.

Add ingredients and their respective quantities as necessary by clicking on the field in the Ingredient column and the Recipe Qty column.

The Other Items tab can include other consumables in this recipe, such as labour and PPE.

Packaging Recipe Procedure

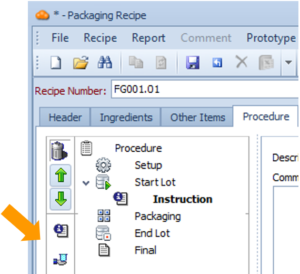

You may also include instructions or tasks in the Procedure tab. This portion of the packaging recipe is not required – you can construct a valid Packaging Recipe without any procedure/instructions.

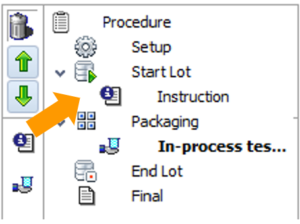

To include tasks into specific sections of the packaging run, drag and drop the respective icons into that section.

In this example, the instruction icon was included in the Start Lot section

Setup refers to tasks that must be performed prior to starting the entire process.

Start Lot refers to tasks that must be performed right before the specific lot must be started.

Packaging refers to tasks that must be performed while the item is being produced. Note that if you wish to include tasks that must be recorded at regular intervals during the production run, you must include them in this section

End Lot refers to tasks that must be performed either at shift end or when the specific lot is in the process of finishing.

Final refers to tasks that must be performed when the complete packaging run has finished

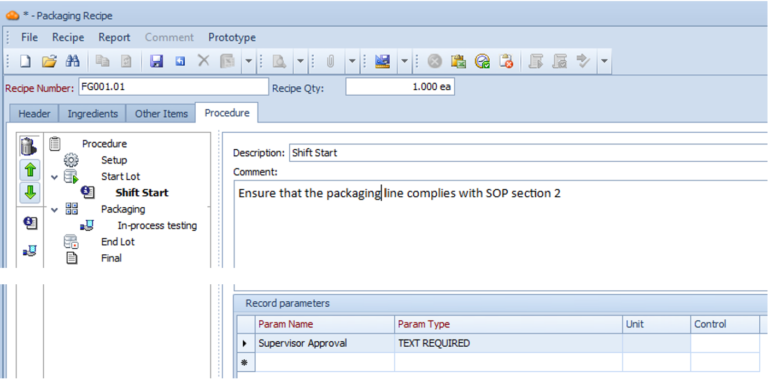

Parameters could also be included in specific tasks. This could be a weight check or a SOP compliance check. Parameters could be numeric (i.e. The pH of the product is within set targets, weight checks) or a text (i.e. Approvals or checks).

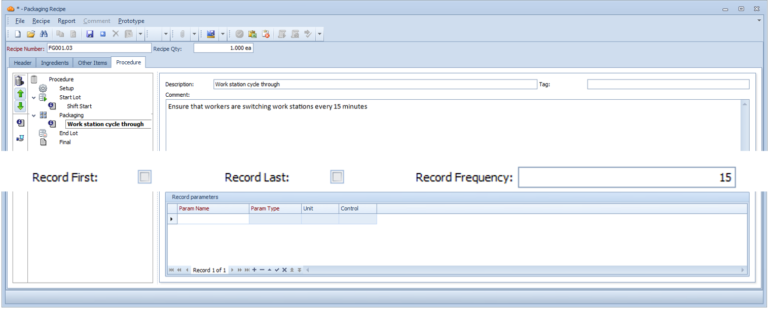

Below is an example of an Instruction and its Parameter.

Below is an example of an instruction task within the packaging step. Note the entry in the Record Frequency field is in minutes units. In this example, the instruction must be performed every 15 minutes during packaging.

Ensure that the Recipe is saved by clicking the Save button or Ctrl + S. You may publish the recipe when it is set to be sent to the Production floor as a Production Order by clicking the ‘Publish’ button.