Work Instruction

In some manufacturing processes, secondary products may be produced at any point during batching. This can be achieved through the alternate packout functionality in Batch Execution. Additionally, certain businesses may also wish to weigh and record cleaning agents used in manufacturing. This is achieved through the End Phase functionality in the Batching Recipe and Batch Execution program.

Batching Recipe

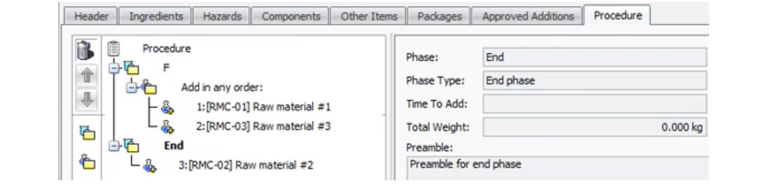

The End Phase is a new Phase Type which is completely independent of all other phases in the recipe. Adding an End Phase to a recipe functions the same way as all other phases in the Batching Recipe program. You may add ingredient steps, instructions, and in process tests to an End Phase. However, the add vessel procedure step cannot be added to the End Phase step and vice versa.

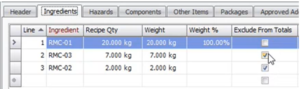

As ingredients may be added to the End Phase, which may not necessarily count towards the total weight and volume for the recipe, there is a column in the Ingredients tab to indicate whether the ingredient should be excluded from the total weight and volume.

Batching Execution

During batching, an alternate packout may be recorded in a phase at any point following the completion of the first step in a phase.

To record an alternate packout, select the Add Alt Packout button.

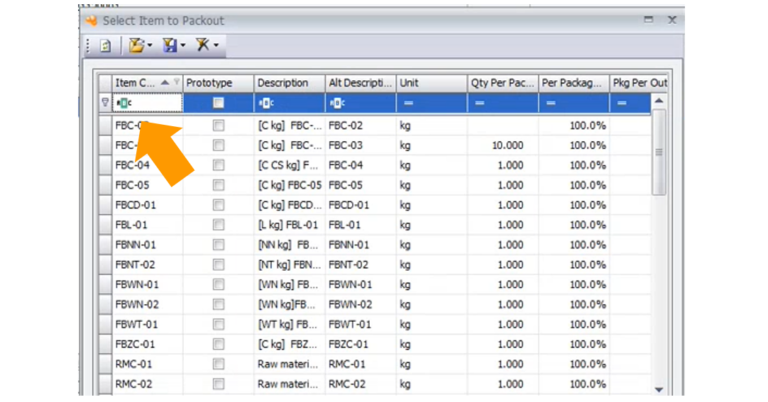

Then select the alternate packout item from the find viewer.

Note: You can only select alternate items with the same unit of measure as the product you are manufacturing.

Note: You cannot select the item the order is manufacturing.

The packaging form will appear and you may record the yield of the alternate packout, similar to recording the batch yield. When the alternate packout yield is recorded, it will appear in the procedure step for that phase.

Note: The quantity for the alternate packout will contribute to the overall yield of the batch.

You may use the Execute Procedure Step button to continue recording outputs for the alternate packout.

To reverse the alternate packout, select the Reverse Alt Packout button.

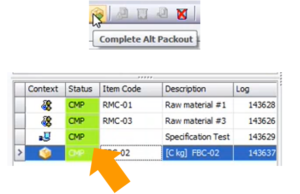

To finish recording outputs for the alternate packout, select the Complete Alt Packout button and the procedure step will be marked as complete.

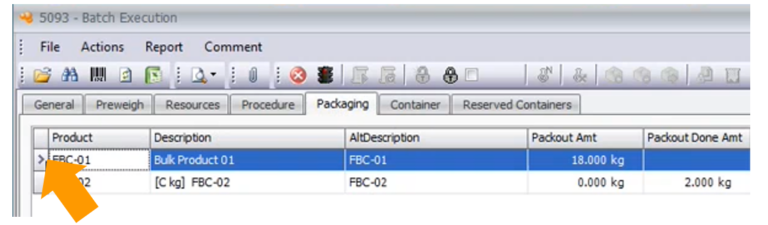

The packaging tab will also display what has been yielded so far in the order, including alternate packouts.

Note: The bulk product that went into the alternate packout will be costed at $0.00.

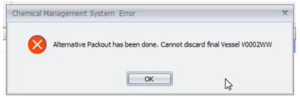

Additionally, the vessel cannot be discarded for any phase with a recorded alternate packout.

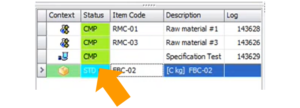

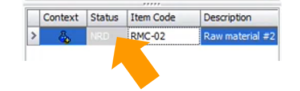

If the batching recipe or order has been set up to include an End Phase, this will appear in the Procedure tab. A status of NRD means “Not Ready” meaning you cannot start this phase at this time.

Once it is time to perform steps in the End Phase, select the Complete Packaging button in the Packaging tab. This button is only enabled if an End Phase is specified for the order. You will not be able to perform any additional packaging for the manufactured product.

Continue following the procedure steps for the End Phase. An alternate packout may also be recorded for the End Phase.

Note: Any alternate packouts completed at the End Phase will not contribute to the overall yield of the order.