The better way of

ERP Software that gives you full control, from raw ingredients to

shipped products.

You need software that will be your single source of truth for everyone in the plant. You want to track everything happening on the shop floor and effortlessly meet your industry-specific requirements. You require maximum visibility to make the right decisions… We’ve got you covered.

Mar-Kov is your ultimate batch manufacturing solution if you

Seamlessly connecting every step of the manufacturing process with our powerful ERP software

99.9%

Inventory accuracy year over year

2X

Production without hiring additional staff

30%

Improvement in margins

60

Seconds to run a mock recall

12

Month ROI

Mar-Kov’s Main Features

- Traceability

- Costing

- World Class MES

- Inventory

- Formulation Control

- Warehousing

- Integrations

- Email Notifications

- Purchase and Sales Orders

Say goodbye to your army of binders, spreadsheets, and files. With Mar-Kov, you can execute a full mock recall in minutes. We make full end-to-end lot traceability effortless. It’s all automated: lot numbers, inventory barcodes, Electronic Batch Records (EBR), and automated Certificates of Analysis (CofAs) at your fingertips.

Learn more

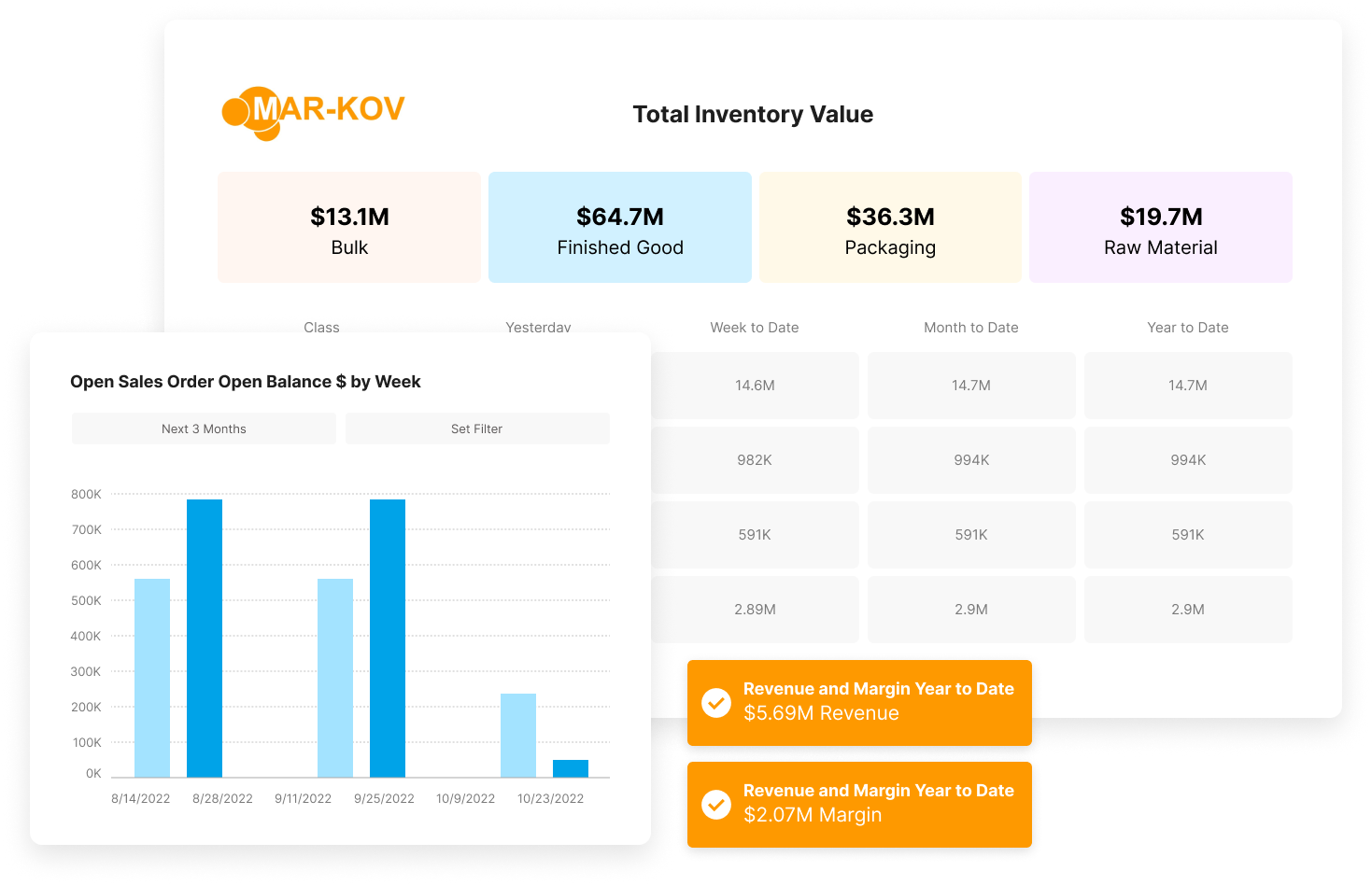

Knowing your costing inside out is key. Mar Kov makes it effortless to know the exact costs of goods sold on a batch-by-batch basis. Seamlessly calculate cost per margin based on raw material prices, and determine your selling price with the click of a button.

Learn more

We make sure that teams are doing the right things in the right ways, without you having to provide constant supervision. Mar Kov prompts and polices operators through the pre-weigh, commingle, and batching operations. We also connect to scales and PLCs (Programmable Logic Controllers) of operational equipment to ensure that every batch is up to par.

Learn more

We help you keep track of everything from receiving raw goods to shipping finished products out: know exactly what you need to buy with the push of a button. barcode your inventory so that you can track its movements, usage, location, and the amount left in each container at any time. Satisfying your sales orders and maintaining your inventory levels has never been so easy!

Learn more

Powerful formulation control is being able to access everything in one place. Recipes, batch records, sign-offs - all you need to make your product exactly how it should be made. Have full revision control of every recipe with easy access to costing information so that you can always be aware of rough pricing for raw ingredients. Never again will your team struggle to figure out what the right way of making something is.

Learn moreWe give you full barcode control so you can track exactly where a product is throughout all of your warehouses. Know exactly where everything is, and the precise amount of inventory you have left at all times. No more frantically running around all four corners of your warehouse to fulfill orders…

Learn more

We integrate with a whole lot of great things. We’ll work with whatever your accounting software and ERP are, and your EDI (Electronic Document Interchange) orders as well as e-Commerce Shopify storefronts. You’ll know exactly what orders to fulfill as they come in. Mar Kov also integrates with your scales, barcode scanners, and PLC equipment, to make for a seamless workday for your whole team.

Learn more

Get instant alerts for everything an issue takes place in your facility. Whether it’s an inventory issue if a client order is at risk, or if equipment needs maintenance, you’ll be in the know. We give you the 360 view you need to run things smoothly, without extra stress.

Learn more

With Mar Kov, you can collect sales orders from everywhere: EDI, e-Commerce, email, phone… Maintain price lists for all your vendors and customers, and know instantly if you have the inventory you need to meet demand across every channel. Track all shipments and lead times and automatically update Shipping and Receiving about all new orders.

Learn moreIndustries we work with

Paint & Coatings

Store formulations securely, maintain accurate inventory and easily track test results

Check it out

Nutraceutical

Safe recipe management, effortless inventory tracking, and constant quality assurance

Check it out“We were kind of set in our ways. After 10+ years of using the same software, we were very reluctant to change. With Mar-Kov, things have worked out better than expected – we replaced all the functionality we had under our old software and have added new capabilities as well. Now we are in a really good place"

John Daly

President of Surfacelogix

“Our formulas are the very foundation of our business and we like knowing they can’t get lost or corrupted, Mar-Kov’s ability to store and instantly access everything from finished goods batch numbers to raw material inventory, and chemical specifications really sold us because it gives us complete control and transparency”

Stephanie Kelly

Quality Manager, Titan Coatings International

Frequently Asked Questions

Blog