Mar-Kov’s Quality Control and Laboratory Information Management System (LIMS) platform streamlines your entire quality workflow, from sampling and testing to release and rework. Centralize your lab data, automate Certificates of Analysis (CoAs), and link quality decisions directly to production. Identify issues early, improve first-pass success rates, and stay audit-ready at all times.

Trusted by:

What Our Clients Are Saying

Built-In Quality Control Features That Power Performance and Compliance

Quarantine and Release

Automatically quarantine raw materials and finished goods. Guide lab teams through test protocols and trigger controlled release based on results.

Automated CoA Generation

Generate Certificates of Analysis automatically from recorded test results. Every product release is backed by traceable quality data.

Rework and Adjustment Enforcement

Define rework or adjustment instructions when a batch is out of spec. Mar-Kov enforces these instructions on the production floor with full traceability.

Trend Analysis and Process Refinement

Use historical quality data to spot trends, tighten specs, and improve process consistency. Drive smarter decisions with data – not guesswork.

Paperless Quality Management

Scheduled Lab Testing

Automate testing requirements by material, product, supplier, or customer. Ensure no test is missed and every spec is verified.

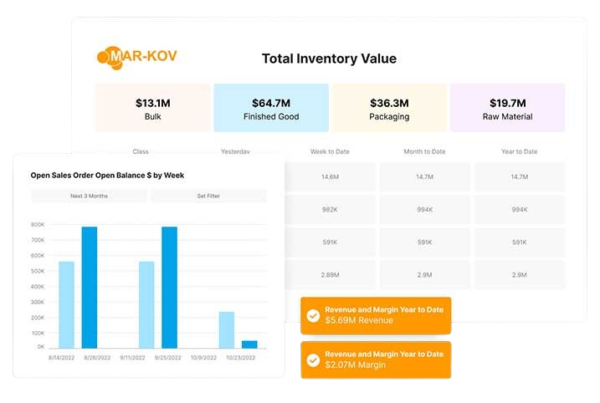

99.9%

Inventory accuracy year over year

2X

Production without hiring additional staff

30%

Improvements in margins

60

Seconds to run a mock recall

12

Months ROI

Ready to take control of quality, without the Paper Trail?

Talk to a Mar-Kov Expert for free