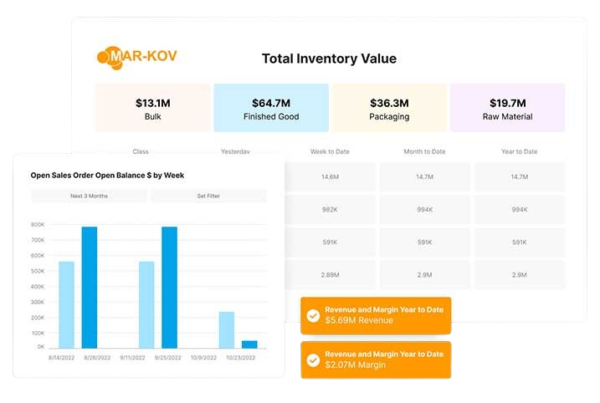

Mar-Kov’s Material Requirements Planning (MRP) software empowers batch manufacturers to stay ahead of demand by connecting real-time inventory, sales, and production schedules. Eliminate stockouts, prevent delays, and automate purchasing with a planning system built for dynamic supply chains. Make faster, data-driven decisions, and keep your operations moving without interruption.

Trusted by:

What Our Clients Are Saying

MRP Features That Keep You Ahead of the Curve

Rapid Response to Market Changes

- Instantly re-plans when forecasts, orders, or supply conditions shift.

- Handles promotional surges, seasonal swings, and product launches with ease.

- Enables agile decision-making with live supply and demand data.

- Simulates scenarios to assess impact before committing changes.

- Coordinates cross-department responses for faster execution.

- Protects margins by aligning procurement, production, and sales strategies.

End-to-End Supply Chain Visibility

- Tracks materials seamlessly from supplier to production line.

- Incorporates lead times of raw materials and production to ensure no missed deadlines.

- Monitors lead times, vendor performance, and quality metrics in real time.

- Flags bottlenecks or shortages before they impact schedules.

- Consolidates data from multiple suppliers, carriers, and warehouses.

- Tracks Supplier approvals and certifications for smoother audits.

Real-Time, Demand-Driven MRP

- Instantly adjusts to changes in sales orders, forecasts, and inventory levels.

- Balances actual customer demand against forecast projections for accuracy.

- Eliminates overproduction and costly stockouts through precise planning.

- Updates material requirements dynamically as production progresses.

- Integrates live data from sales, procurement, and warehouse systems.

- Alerts you when a customer order on minimum inventory are at risk.

Shelf-Life & Expiry-Aware Scheduling

- Prioritizes raw materials and ingredients by expiration date.

- Plans production to minimize waste, spoilage, and costly rework.

- Ensures compliance with food safety, pharma, or chemical regulations.

- Automatically rotates stock based on FIFO/FEFO rules.

- Tracks expiry risk at every stage from receiving to finished goods.

- Adjusts schedules when supplier delays threaten shelf-life targets.

99.9%

Inventory accuracy year over year

2X

Production without hiring additional staff

30%

Improvements in margins

60

Seconds to run a mock recall

12

Months ROI

Drive Growth with These Key Business Benefits

Expertise Across Industries

Unlock More Powerful Features

Work Smarter With Seamless Integrations