Key Takeaways:

- Tariffs are introducing surprise costs, margin pressure, and fulfilment risk for manufacturing businesses.

- Overreliance on outdated tools or single suppliers increases vulnerability.

- MES (Manufacturing Execution Systems) improve inventory accuracy and enable real-time tracking of landed costs — giving manufacturers the visibility they need to control expenses and stay agile.

- Integrated systems enable faster decisions across sourcing, production, and finance.

- Expert insights from China sourcing consultant John Kyle Beaton of China Product Pros, underscore the need for proactive planning.

Why Tariffs Matter for Manufacturing Businesses

For North American manufacturing businesses—especially those in food, cosmetics, chemicals, and pharmaceuticals—tariffs are no longer abstract policy threats. They are a direct, measurable pressure on cost structures, lead times, and supplier reliability.

Increased tariffs on raw materials, packaging, or machinery can push per-unit costs up by 10% to 30%, undermining profit margins and complicating competitive pricing. More than that, sudden changes in policy can bring unforeseen delays or require urgent shifts in supplier relationships, often under tight timelines.

”This isn’t just a trade issue—it’s an operational one. Tariff risk touches every aspect of manufacturing, from procurement and planning to finance and customer delivery.

The most exposed companies tend to rely on legacy systems, disjointed workflows, or manual processes that lack real-time visibility into cost drivers. These gaps make it hard to simulate scenarios, model cost increases, or communicate tariff impact across teams.

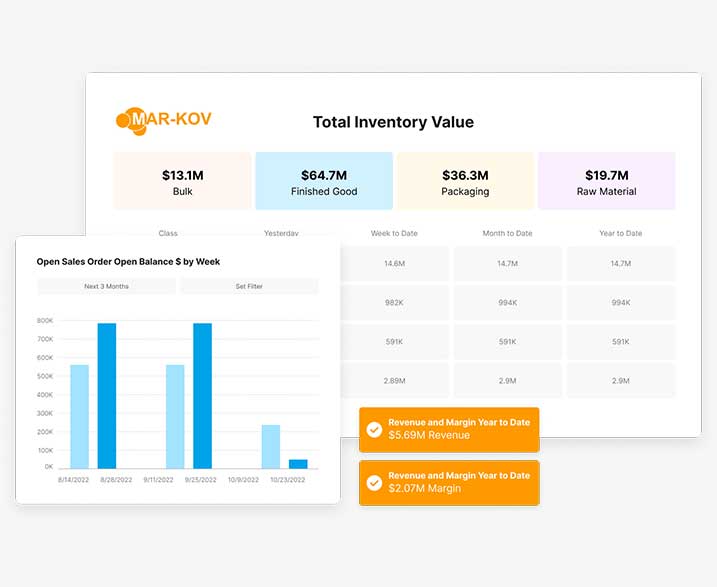

Manufacturers who have adapted more agile systems, including integrated ERP software like Mar-Kov’s enterprise resource planning ERP systems, are in a stronger position to absorb, forecast, and respond to external shocks like tariffs.

Don’t Panic: Use Data to Drive Smarter Sourcing Decisions

Tariffs tend to cause knee-jerk reactions. But in the long term, the winners are those who resist panic and turn to data. The ability to base decisions on real-time costs, vendor performance, and product demand allows manufacturers to respond with precision rather than fear.

Ask your team:

- Are we tracking landed costs dynamically, or relying on outdated averages?

- Can we run what-if simulations to compare sourcing strategies under different tariff conditions?

- Do our procurement and finance teams work from the same real-time data?

Without these capabilities, you’re likely flying blind.

Modern enterprise resource planning systems allow manufacturers to centralize purchasing, costing, and production data in one place. That means sourcing teams can work directly with finance to forecast margin impacts, adjust order quantities, or pursue volume-based cost efficiencies. By using enterprise resource system tools such as Mar-Kov’s ERP, manufacturers can run side-by-side comparisons of sourcing from China versus Mexico, the U.S., or Europe—and make decisions based on total landed cost and speed to market.

John Kyle Beaton, featured in Episode 4 of the Better Batch Podcast, advised manufacturers to adopt a mid-range view: resist the urgency to switch vendors overnight and instead simulate outcomes based on data. The goal is not immediate disruption, but strategic flexibility.

Actionable Tips:

Supplier Diversification: Avoiding Over-Reliance on Single Suppliers

One of the most effective ways to mitigate tariff risk is supplier diversification. Yet many manufacturers still rely heavily on a single vendor or region for critical materials or components. This introduces a fragility that’s only amplified during trade disruptions.

Diversification isn’t only geographic—it’s operational. That means qualifying secondary vendors, setting up alternate BOMs, and preparing procurement teams with clear onboarding processes.

Recommendations:

”To diversify effectively, manufacturers must have systems that support complexity. A basic accounting tool or inventory spreadsheet won't help you coordinate two vendors supplying the same part with different lead times and cost profiles.

This is where manufacturing resource planning and enterprise resource management systems make a difference. With the right software, you can:

- Set up alternate sourcing logic based on inventory levels, geography, or cost.

- Compare production impact based on switching inputs or materials.

- Free up your team’s time to focus on higher-value tasks like supplier validation and compliance by eliminating manual admin with software-driven workflows.

Diversification isn’t simply a risk-reduction play, it’s a competitiveness strategy. The more nimble your procurement process is, the more opportunities you can capture when others are constrained.

How an ERP System Can Help You Manage Sourcing Risk

Many manufacturers still view ERP as a business and finance tool but in today’s business landscape, it’s the backbone of your sourcing strategy.

A modern enterprise resource planning ERP system, such as Mar-Kov’s, doesn’t just help you cut costs. It gives you the clarity to make better trade-offs, faster. The system acts as a hub between purchasing, inventory, production, quality, and finance.

With a fully integrated ERP system, you can:

- Centralize vendor data, including historical performance, cost changes, and audit results.

- Link every material input to its respective supplier contract and pricing terms.

- Generate production schedules that factor in supplier lead time variability.

Additional Advantages:

- Live costing lets finance and procurement see real-time margin impact.

- QA can enforce compliance standards from day one using built-in SOP enforcement.

- Production avoids bottlenecks caused by late or inconsistent deliveries.

If you’re still managing vendor relationships through email and spreadsheets, you’re likely missing early warning signs and leaving your team vulnerable to surprise disruptions.

”One often missed advantage of integration is that connecting your enterprise resource management system with procurement tools ensures every purchase order is supported by accurate and up to date costing and compliance data. This improves confidence in critical purchasing decisions.

Choose Mid-Term Planning Over Short-Term Panic

Tariffs are part of a broader volatility trend in global manufacturing. Whether it’s geopolitics, climate risk, or changing regulations, uncertainty is the new norm. What separates resilient manufacturers from reactive ones is infrastructure. That means data, systems, processes and mindset.

Here’s what you can do now:

- Run a supply chain simulation: What if one of your top three suppliers increased prices by 25%?

- Review your vendor diversification ratio: Are more than 60% of your inputs coming from a single country?

- Evaluate whether your ERP software allows real-time collaboration between sourcing and finance.

- Invest in tools that reinforce transparency, automation, and scenario planning.

”Remember: tariff uncertainty is not a temporary storm. It’s part of a shifting global landscape that demands better tools and sharper decision-making.

With the right systems in place such as enterprise resource planning, manufacturing execution systems, and enterprise resource planning—manufacturers gain not just control, but strategic leverage.

Mar-Kov helps you turn volatility into opportunity by improving traceability, reducing errors, and enabling smarter decision-making at every stage of production.

Curious how it could work for your team? Book a demo to see how Mar-Kov supports manufacturers navigating uncertainty with confidence.

You May Also Like:

The Better Batch Podcast: How to Source & Manufacture Products from China | Strategic Procurement in Uncertain Times

Frequently Asked Questions About Tariffs

About the Author

Peter Suddard has worked with batch process manufacturers for years, helping them scale and improve their business.