Tracking allows you to keep track of the materials directly and indirectly used in the manufacturing process. Allowing the organization to set up traceability on a per item basis.

Tutorial Video

Mar-Kov Traceability Options

Container, Lot trace

– Inventory for this item is tracked by container

– Each manufacturing lot in inventory will consist of one or more containers (sublots)

– Each container will have its own unique container number, and inventory quantity will be tracked for the container as shown below.

– During manufacturing, you can track which containers are being used and how much has been used from each container.

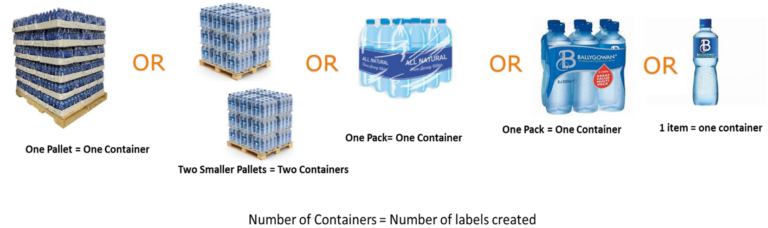

Note: A container can either be a pack, a pallet, or an individual item.

For example:

Advantages of using Container, Lot Trace

– Child/Parent Traceability (Forward and Backward Traceability)

The generated lot number allows for full traceability. The Trace Child (Forward Traceability) feature lets you select a container and see all inventory that was made using that specific lot. This is the idea of tracing components and raw materials all the way to the finished product and consumers.

The trace Parent (Backward Traceability) feature allows you to select a container and see where the product originally came from. Backward traceability allows you to follow the journey of a finished product all the way back to the original sources of the raw materials.

When a quality incident occurs, lot traceability means that an enterprise can analyse the root cause of the issue and uncover the problematic material.

– Storage Rules

Mar-Kov can create location storage rules to determine if inventory containers are in illegal locations, for instance to see if a material must be kept in a warm or refrigerated area. This feature is only possible when inventory is tracked by container because the location of the container is used.

– Staging

Staging is a feature that allows you to find containers that are required by manufacturing orders and return containers in stock that are no longer required by manufacturing orders.

– Better inventory control

View your stock movements around your warehouse; easily identify missing stock

– Perform Tests on Multiple Sublots

Select multiple sublots for testing and compare data for get accurate and reliable results

– Optimized inventory usage

Optimize inventory usage and Avoid Spoilage through FEFO (First Expiry, First Out) and FIFO (First In, First Out)

Disadvantages of using Container, Lot Trace

– Relatively effortful

You need to print multiple labels and attach them to your containers.

All containers to be used need to be scanned all the time for manufacturing, packaging, and shipping.

This is a precise tracking method and therefore, it takes a lot of effort to implement.

Inventory, No Lot trace

– Inventory for this item is tracked by warehouse. You can track the total amount inventory quantity present in each warehouse for a particular product

– This option is used when you want to track which lots of this item are stocked, you will not track a lot number for this item. It is commonly used for tracking packaging material

– During manufacturing, you only need to specify the total quantity of the materials used

Advantages of Inventory, No Lot Trace

– Simple and easy to set up

– No need to print barcode labels

– Easier and quicker to use in production. No scanning required during manufacturing and shipping

– Track your total inventory of a given item in the warehouse

Disadvantages of Inventory, No Lot Trace

– No full traceability of your inventory. In case of recalls, you will not be able to trace your inventory back to raw materials and vice versa

– Cannot optimize inventory which could cause spoilage

– Cannot track movement around the warehouse

– Cannot set storage rules for your inventory

– Unable to identify different sublots for testing purposes.

Summary

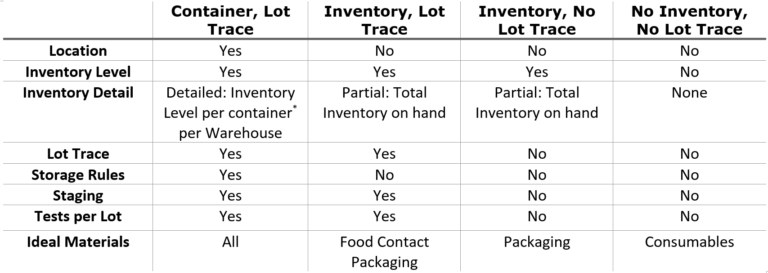

The table below highlights a summary of the key features that are determined by the chosen tracking type: