Mar-Kov’s Inventory and Warehouse Management feature is purpose-built for batch process manufacturers, combining robust automation, real-time traceability, and compliance controls. From barcode scanning and FIFO enforcement to expiry management and audit-ready cycle counts, you’ll streamline your operations, reduce waste, and stay always inventory accurate.

Trusted by:

What Our Clients Are Saying

Explore Mar-Kov’s Inventory & Warehouse Management Features

Full Barcode Control

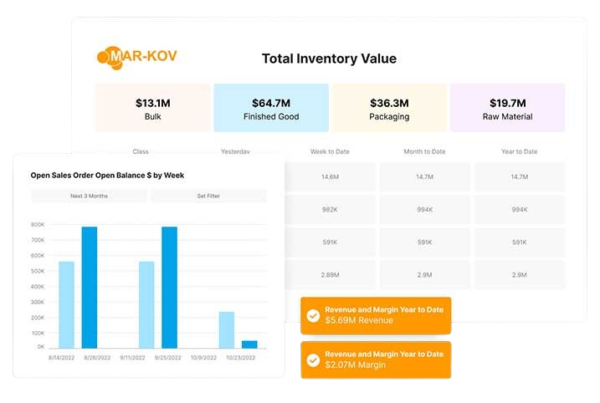

- Instantly view inventory levels by item, lot, location, and status across all facilities.

- Track available, reserved, quarantined, and expired stock in real time.

- Enable data-driven decision making with live dashboards and customizable KPIs.

- Generate automated reports for production planning, replenishment, and audits.

- Analyze historical movement trends to identify shrinkage, spoilage, or bottlenecks.

- Export filtered reports by product class, customer, supplier, or storage conditions.

Advanced Location, Lot, and LPN Tracking

- Track inventory by precise warehouse location, down to aisle, row, shelf, and bin.

- Assign and manage License Plate Numbers (LPNs) to track containers, totes, or pallets.

- Maintain complete lot-level traceability from receiving through shipping.

- Support nested tracking (e.g., containers inside pallets inside zones).

- Quickly locate any item or material using mobile scan lookup or advanced search.

- Facilitate rapid recall or QA investigations with full movement history.

FIFO/FEFO Enforcement & Expiry Management

- Automatically enforce FIFO or FEFO picking logic during staging and fulfillment.

- Configure rules by product type, customer, or regulatory requirements.

- Receive alerts and visual flags for soon-to-expire or expired inventory.

- Trigger automatic reclassification or rotation based on expiry risk.

- Prevent usage or shipment of expired or non-compliant stock with enforced rules.

- Maintain audit-ready expiry logs and shelf-life tracking by lot or LPN.

Intelligent Staging

- Automatically stage items by priority, order, or production schedule.

- Optimize staging location selection based on proximity, zone rules, and capacity.

- Use barcode scans to confirm correct staging placement and reduce errors.

- Support multi-order or multi-batch staging with clear visual workflows.

Easy Cycle Counts

Rule-Based Storage Zone Enforcement

- Define digital rules for zones: quarantine, allergens, flammables, temperature-controlled, etc.

- Automatically restrict placement of incompatible items in shared areas.

- Alert staff and block transactions that violate zone rules or safety protocols.

- Use barcode scan validation to confirm proper storage at receiving or transfer.

- Maintain compliance with GFSI, FDA, or other regulatory standards through enforced segregation.

99.9%

Inventory accuracy year over year

2X

Production without hiring additional staff

30%

Improvements in margins

60

Seconds to run a mock recall

12

Months ROI