Mar-Kov’s Manufacturing Execution System (MES) equips batch manufacturers with the tools to enforce SOPs, eliminate manual errors, and capture every production detail from start to finish. Whether you’re weighing, blending, packaging, or cleaning, Mar-Kov enables you to run operations with precision and produce audit-ready electronic batch records (EBRs) every time.

Trusted by:

What Our Clients Are Saying

Built-In MES Capabilities That Keep Production on Track

Barcode-Enforced Workflows

- Direct operators through step-by-step production using barcode scanning.

- Verify material identity, lot numbers, and quantities before each addition.

- Ensure the correct equipment is used and properly cleaned before use.

- Prevent skipped steps, missed samples, or out-of-sequence actions.

- Block progress if validations fail, reinforcing compliance and accuracy.

- Create a consistent, error-resistant manufacturing process.

Equipment & Cleaning Logs

- Digitally log equipment usage, downtime, and cleaning events.

- Automate cleaning validation schedules based on time, usage, or batch.

- Require barcode scanning to confirm cleaning and inspection completion.

- Enforce pre-use checks and track which operators performed them.

- Keep detailed logs for inspections, audits, or root cause analysis.

- Link cleaning history to production batches for full traceability.

In-Process Instructions and QA Controls

- Display real-time work instructions customized by product or batch.

- Prompt operators for measurements, weights, and other checkpoints.

- Require electronic sign-offs at critical control points.

- Automatically flag out-of-spec data and enforce corrective action workflows.

- Link quality checks directly to individual batches or steps.

- Reduce deviation investigations with built-in process documentation.

Automated Weighing and PLC

- Connect directly to scales to capture weights without manual entry.

- Automatically validate weights against batch tolerances.

- 21 CFR Part 11 compliant electronic signatures.

- Speed up weighing steps with automatic tare and net weight calculation.

- Track weighing history and link it to materials, lots, and operators.

- Support Gang/Campaign Weigh, Reverse Weigh, Weigh by bag and more to match how you do production.

Digital Batch Records (EBRs)

- Capture all production activity in a single digital batch record.

- Automatically log timestamps, materials used, equipment, and operator actions.

- Require electronic signatures at each step for compliance.

- Attach QA data, deviations, and approvals in real time.

- Generate complete audit-ready reports in a single click.

- Meet regulatory requirements for all standards.

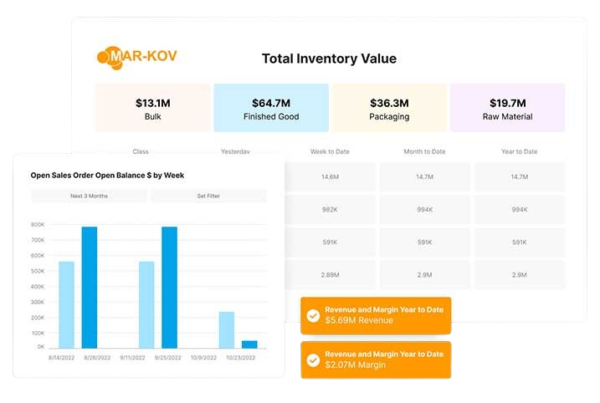

99.9%

Inventory accuracy year over year

2X

Production without hiring additional staff

30%

Improvements in margins

60

Seconds to run a mock recall

12

Months ROI

Ready to bring Order, Accuracy, and Compliance to Your Production Floor?

Talk to a Mar-Kov Expert for free