1

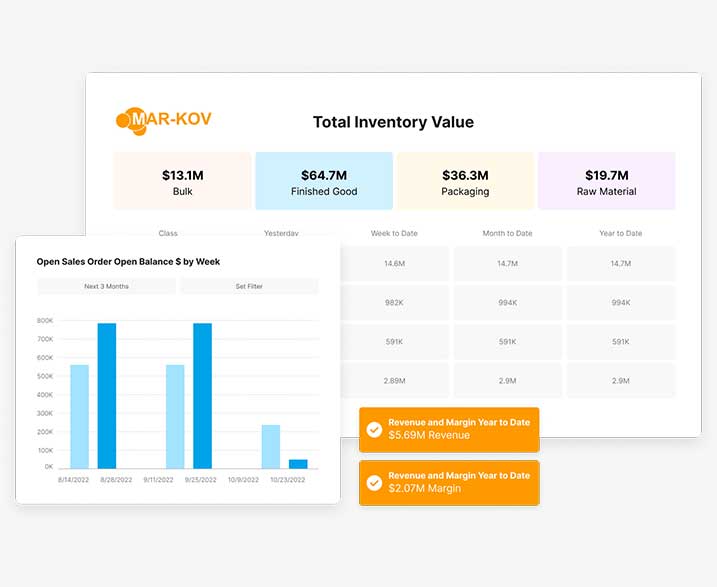

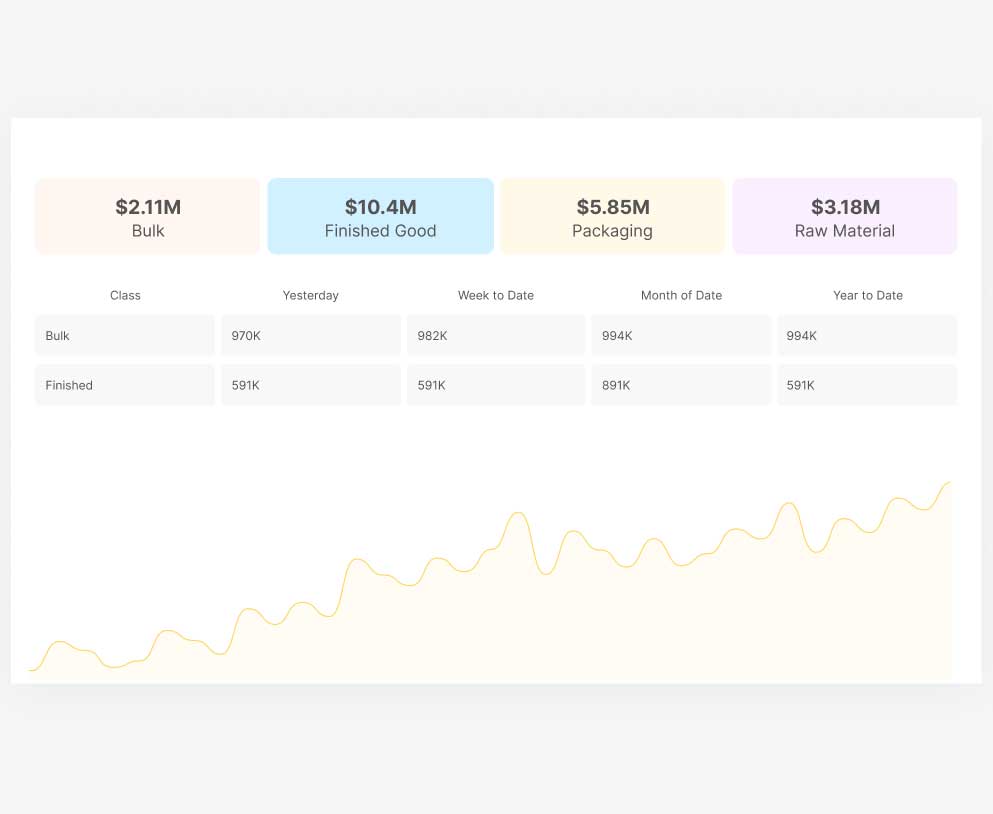

Can Mar-Kov help me monitor profit margins for the different Pharmaceutical lines?

Yes, Mar-Kov’s margin tracking tools let you analyze profitability by product, SKU, customer, or batch. You can view contribution margins in real time and drill into cost components like raw materials, labor, and waste. With built-in reporting, you can easily identify underperforming products and take corrective action—whether that means price adjustments, sourcing changes, or process improvements.2

Can Pharma Manufacturers use QuickBooks with Mar-Kov?

Yes, Mar-Kov integrates seamlessly with both QuickBooks Online and QuickBooks Desktop. Our integration enables automatic syncing of financial data such as purchase orders, vendor invoices, inventory adjustments, and batch costing. This ensures that your production and accounting systems stay in sync—reducing double data entry, minimizing errors, and saving valuable time for your finance team. Mar-Kov manages Inventory, BOMs, and Production, QuickBooks Manages accounts payable, accounts receivable, and general ledger.3

How does Mar-Kov’s Pharmaceutical ERP track quality data?

Yes—Mar-Kov includes a fully integrated quality management system (QMS) designed specifically for pharmaceutical manufacturing. Our platform tracks and enforces required testing and sampling at every stage: raw materials, in-process production, and finished goods. You can configure electronic quality holds and quarantines to automatically prevent non-compliant materials or batches from progressing through the workflow. All test results, deviations, and Certificates of Analysis (COAs) are logged within the system, ensuring complete traceability and regulatory compliance—without needing third-party QA software.4

How does Mar-Kov support GMP compliance in pharma manufacturing?

Mar-Kov is designed to align with GMP standards by enforcing documented procedures, audit trails, and material traceability throughout your operations. The system ensures that all actions—from raw material receipt to finished product release—are recorded and verifiable. 21 CFR Part 11 compliant Electronic signatures, access controls, and automated workflows help you maintain a state of continuous compliance and prepare for inspections with confidence. Mar-Kov can also guid FDA audits are a breeze.5

How can I track the cost of goods sold (COGS) in pharma manufacturing?

Mar-Kov automatically calculates COGS for every batch using actual material costs, labor time, and landed costs, Our system records real-time consumption and yields, providing an accurate cost profile for every product. You can compare planned vs. actual costs and quickly identify variance drivers—empowering better pricing and profitability analysis.6

How does Mar-Kov support cost optimization in pharmaceutical manufacturing?

Mar-Kov helps you reduce costs through:

Real-time yield monitoring and waste reduction analytics

Supplier price comparison and procurement insights

“What-if” cost modeling for formulation changes

Automated reorder suggestions to avoid rush purchases By having full cost visibility at every level of production, you can optimize both pricing strategies and operational efficiency.

7

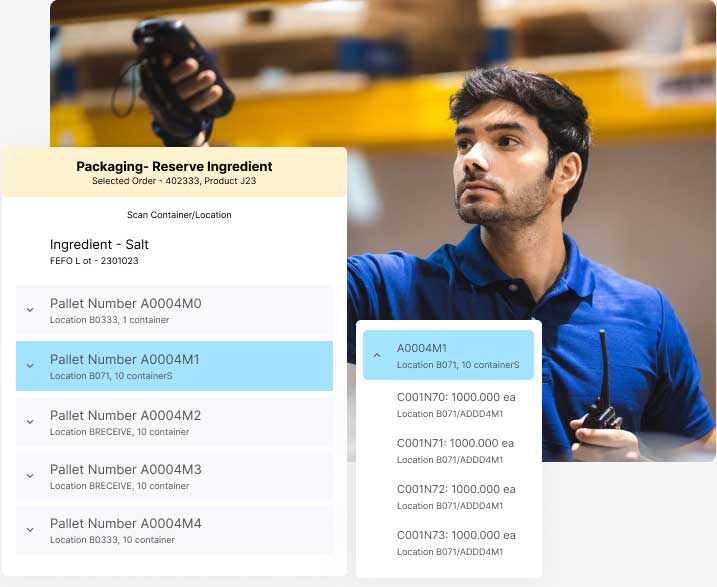

How does the pharmaceutical Manufacturing Execution System (MES) work?

Mar-Kov's Manufacturing Execution System (MES) bridges the gap between planning and production by managing and monitoring real-time shop floor operations. The system will confirm scale calibration and equipment cleaning with signature enforced workflows. Mar-Kov's MES integrates with your scales, equipment, and barcoding to direct your operators through each step and checks to make sure they perform it correctly. This automatically updates inventory, creates Electronic Batch Records, and ensures a perfect batch every time.8

How does the chemical Manufacturing Execution System (MES) work?

Mar-Kov's Manufacturing Execution System (MES) bridges the gap between planning and production by managing and monitoring real-time shop floor operations. Mar-Kov's MES integrates with your scales, equipment, and barcoding to direct your operators through each step and checks to make sure they perform it correctly. This automatically updates inventory, creates Electronic Batch Records, and ensures a perfect batch every time.