The better way of

Here’s what we’ll show you:

Companies using Mar-Kov for brilliant batch-manufacturing

Flawlessly execute every step of your food manufacturing process with effortless automation

99.9%

Inventory accuracy year over year

30%

Improvement in margins

2X

Production without hiring additional staff

60

Seconds to run a mock recall

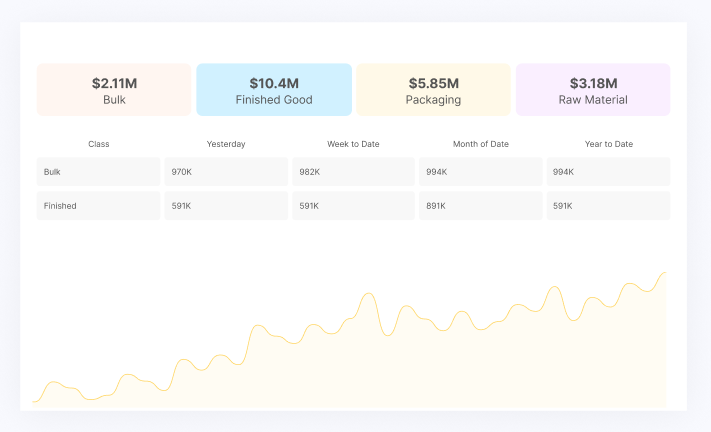

Costing & Analysis

Know the exact costs of goods sold on a batch-by-batch basis. Instantly understand what fluctuations in raw material costs do to your bottom line. Seamlessly calculate cost per margin based on raw material prices, and determine your selling price with the click of a button.

Inventory Management

Keep track of everything from receiving raw goods to shipping finished products out with barcoded inventory. Know when each lot will expire with foolproof reports, be notified of shortages and plan production through automatically generated MRP alerts. Track and manage all of your allergens to ensure GMP compliance.

Traceability

Ace your next food safety audit with our bulletproof traceability feature set. Execute a full mock recall in minutes and get full end-to-end lot traceability, with auto-generated lot numbers and inventory barcodes. Mar-Kov creates automated Electronic Batch Records (EBR) for every batch.

Integrations

We integrate with your accounting software, ERP, EDI (Electronic Document Interchange) orders and e-Commerce Shopify storefronts. You’ll know exactly what orders to fulfill as they come in. Mar-Kov also integrates with your scales, barcode scanners, and PLC equipment.

“We can track every gram that arrived in a 20,000 lb container and that blows auditors’ minds.

— Chaz Fulcher, co-founder, Fulcher’s Seafood

“Push a button and Mar-Kov delivers these incredible reports that track costs, pricing and selling patterns”

— Emily Julian, Chief Operating Officer, Moo Thru Ice Cream

“The truth is, when I contacted Mar-Kov, they answered yes to my entire requirements list.”

— Janet Coursin, project manager.