Tutorial Video

Work Instruction

Batching Order Demand

This feature is used for Batching Orders that require packaging where you do not wish to create and execute a Packaging Order to produce the final product.

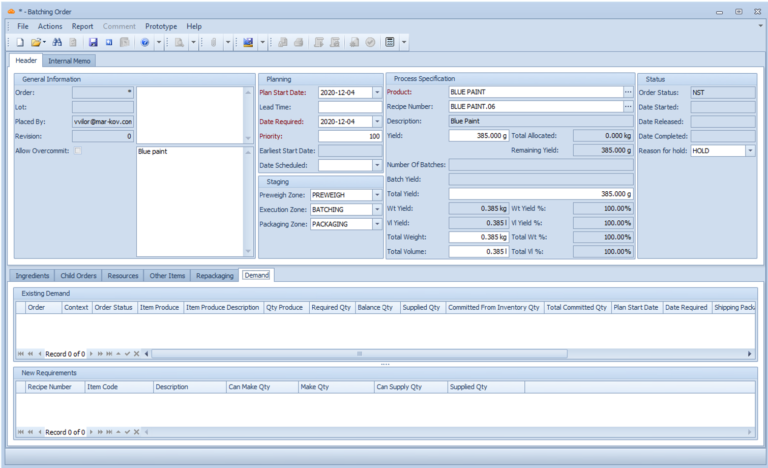

Create and save a new Batching Order:

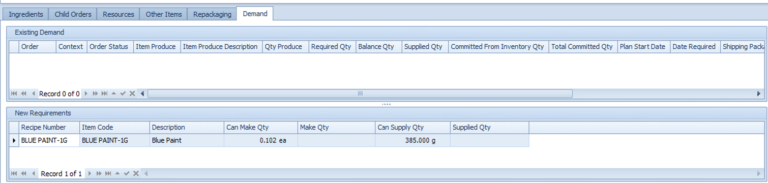

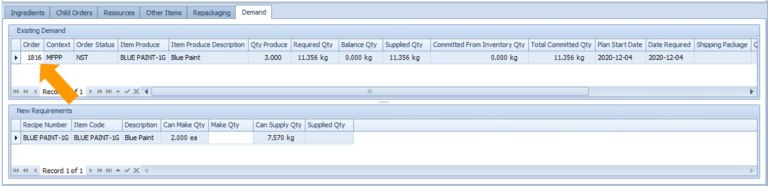

After clicking the save button the system will look up all the packaging options available to package the product. On the Demand tab the Packaging Recipe(s) for the final product will be shown:

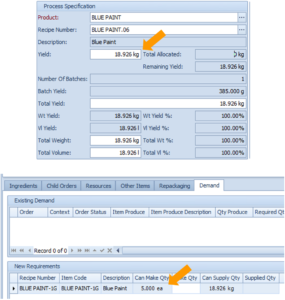

Based on the recipe yield specified, five units of the final product can be produced.

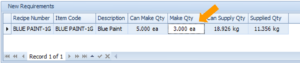

In the Make Qty column, specify the number of units you would like to manufacture, and save the form again.

A new order number will be created. This will now be an available packaging option when you process the order in Batch Execution Express.

Release the Batching Order.

Packing out the final product

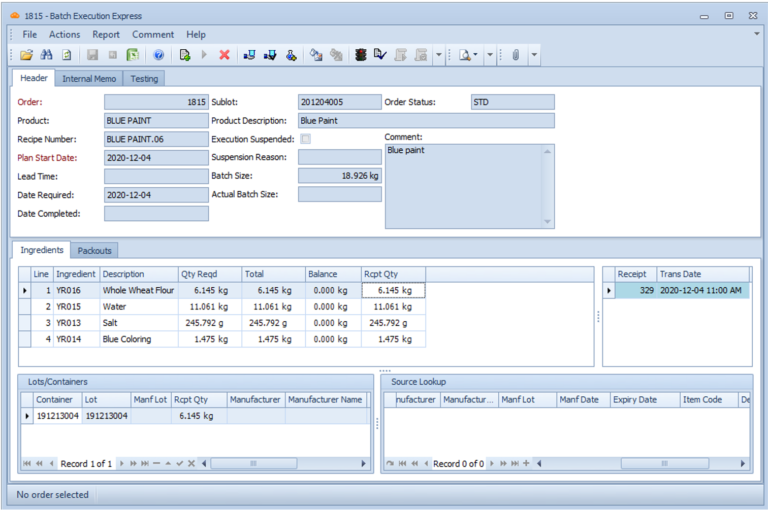

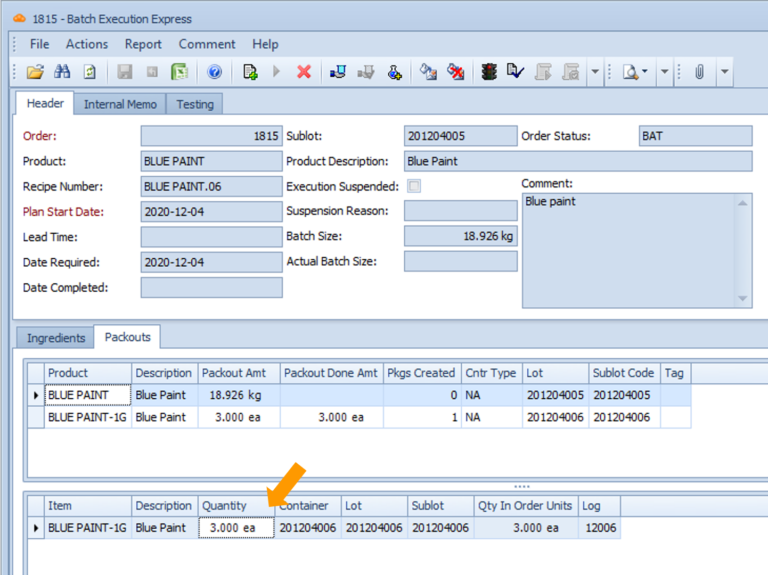

In the Batch Execution Express form:

- Create a Batch Receipt

- Document all the quantities consumed

- Save the form

(for the details, refer to the Batch Execution Express work instruction)

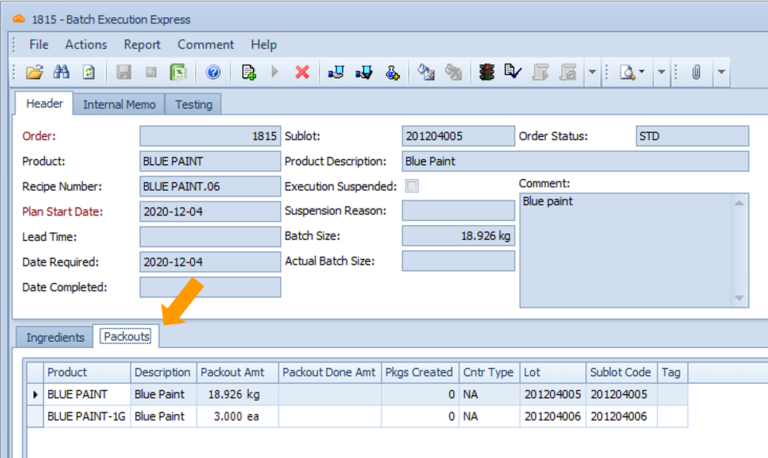

Select the Packouts tab. Here you have two options:

- You can pack out the intermediate product (BLUE PAINT)

- You can pack out the final product (BLUE-PAINT-1G)

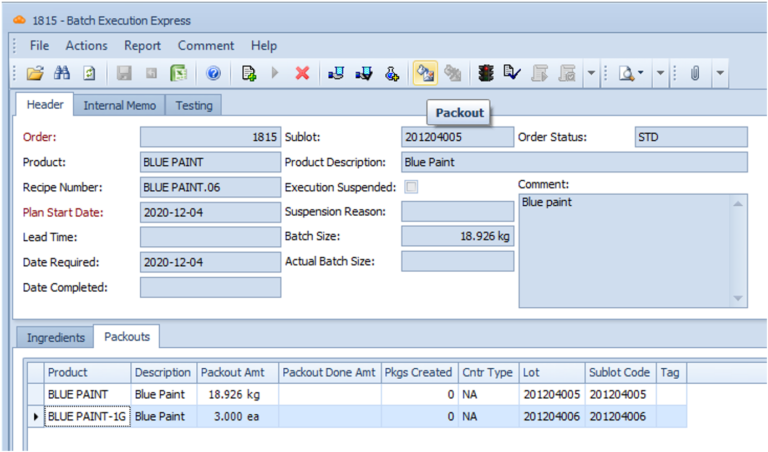

Click the option for the final product add hit the ‘Packout’ button

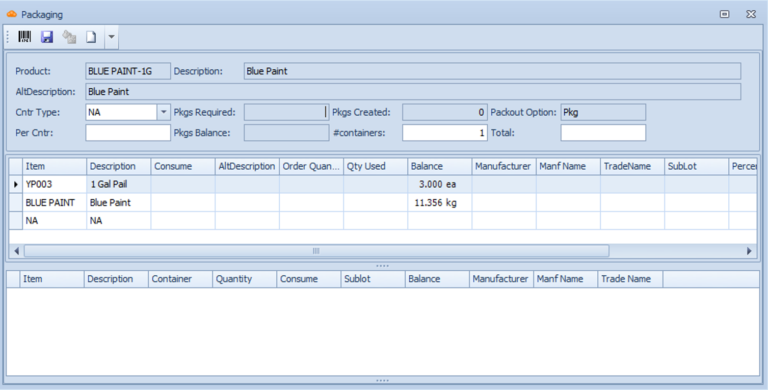

The components needed to make 3-gallon containers of Blue Paint will be shown.

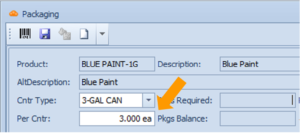

Specify the Container Type and the quantity in the container.

Click Save to confirm.

A 3-gallon container will be created

Mark the order complete by hitting the ‘Mark Order Complete’ button.